Why are some most advanced structures not everlasting?

We witness that many structures built by humans, even the most advanced ones, are not everlasting. Aside from perhaps poor details in architecture, improper usage of materials or wrong installation of materials leads to penetration of water which causes serious damage to the structure. Serious damage to these structures can lessen not only the monetary value but also the visual and aesthetic appeal along with structural integrity. In this article, we will highlight the best waterproofing chemicals for you.

The need for Waterproofing

Waterproofing is a term that is commonly used to describe building constructions (such as basements, decks, or damp areas), boats, canvas, clothing (raincoats or waders), electrical equipment and paper packaging that are water-resistant. Due to waterproofing, the structure remains relatively impervious to water under specified conditions increasing its life.

Best Chemicals used in waterproofing

One of the common methods of waterproofing is chemical waterproofing, and we will focus on the best chemicals used for waterproofing here. Below mentioned are some of the chemicals used in Waterproofing Methods-

Tuffcrete

It is an acrylic copolymer emulsion-based additive. Tuffcrete can be used as a coating for cement-based structures, or also as mortar and screed. This substance enhances both mechanical properties which include compressive strength, tensile strength, and adhesive strength, and water-resisting strength of the structure. It provides many advantages such as excellent breathing properties, reducing corrosion, and resistance to weathering effects. Its coating can be used for applications involving continuous contact with water.

Vinyl Ester Resin System

The chemical properties of the resin in this system create waterproof membranes which guard the object against moisture and water damage. Vinyl Ester Resin System can be applied as a coating, slurry, or mortar mixture. Additionally, it also helps in preventing acid and corrosion damage.

Polyurea Coating

Owing to its molecular properties as a polymer, polyurea can be called one of the most resilient and flexible protective coatings making it both water as well as abrasion-resistant. Polyurea Coating has antimicrobial effects as well.

Polyurethane Liquid

It is composed of organic units joined by links of urethane. It is a class of polymers, rather than being a distinct compound that is primarily used for waterproofing exposed areas. Although flexible, Polyurethane Liquid should be applied on flat surfaces without any rises or disturbances so as not to elevate the moisture levels of the concrete surface, which can result in the debonding of membranes, consequently leading to the throwing off of the entire process. Although it is a very effective process but also a very costly one.

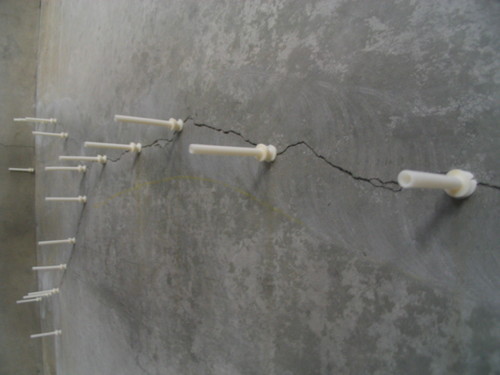

Grout and Epoxy Injection

Grout is a dense fluid made up of water, cement and sand combination; employed in pressure grouting, the embedding of vertical iron rods in walls, making connections between sections of precast concrete, void filling, and sealing joints such as those between tiles. Epoxy is made up of chains of carbon linked to other elements such as hydrogen and nitrogen. These chemicals can be used to waterproof a crack site in concrete by injecting the fluid or drilling holes into the surface to insert the material or the mixture. The mixture inside reacts with water in the site, forming a sealant of these chemicals which effectively creates a water-resistant barrier in the former crack’s place.

Crystallization Waterproofing

Different from conventional methods, it is a very effective method of waterproofing. It is used extensively for waterproofing purposes in Europe and America. In this method, crystalline chemicals create a reaction that causes long, narrow lines of crystals. This helps to grow and develop, filling the hairline cracks and pores of the concrete. The growth of these crystals continues till moisture is available. When the concrete is dry, these chemicals sit dormant till more moisture becomes available. Furthermore, prompting the reaction to start again leading to the development of the crystals again. The chemicals sit deep within the concrete, becoming an integral part of the structure and providing long-lasting protection to the structure.

Bituminous Waterproofing Method

Also known as asphalt coating, is a dark pitch substance of combined sand and gravel. Its waterproofing characteristics are determined by the polymer grade and the fibre content of the chemicals.

Final words

We have seen how important it is to make structures waterproof for maximum efficiency and strength in the long run. Although there are many methods of waterproofing, they work externally while chemical methods of waterproofing work both externally and internally. These substances mentioned above are chemicals, used for waterproofing, that forms an integral part of the structure itself, leading to strengthening of the structure and protection against water hazards.

Also, know about the Best Portable Speakers for iPod